Removable Template Reed Chip.

Reed Chip - Product Vision.

The profile of a double reed shape, e.g. an oboe reed shape has to be adjusted to the player, his instrument and is also responsible for the spectrum of the sound. Profiling machines are using templates which represent one shape profile. With this new approach it is easy to make individual shape profiles and because the produced template is like a reed-hardware chip cheap to produce and fast to be inserted in a profiling machine it could be used also for experiments or making reeds for different events and conditions.

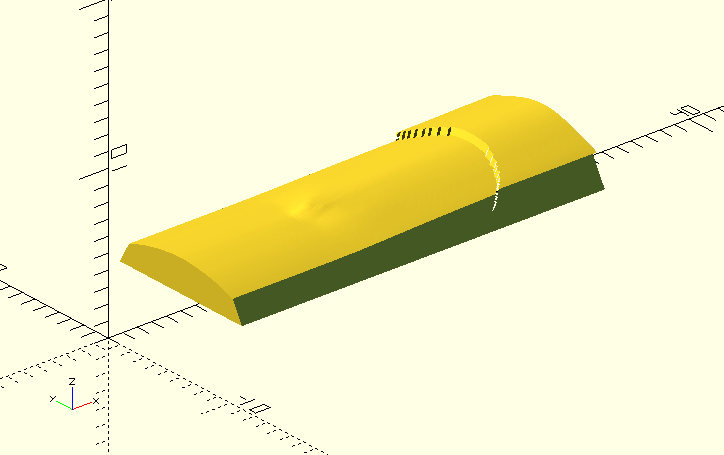

Oboe Reed Profiling Template

The reed profile technique will be used for wood oboe reeds or english horn reeds. Today market with reeds made from wood is still in progress. Most factories of the profiling machine will sell the machine by one template profile (with an exception by the Bucher machine where the machine has 6 different profiles built in). The profiling machine from oboe-atelier by W.Wettstein has one profile which can be customized before the order. A customized metal profile is very expensive and not applicable by experience.

Requirement

Reed shape profile tool with an adapter for the reed chip E.g.

Process oriented solution: A reed form chip

The core element is easy interchangeable a like a memory stick in a camera

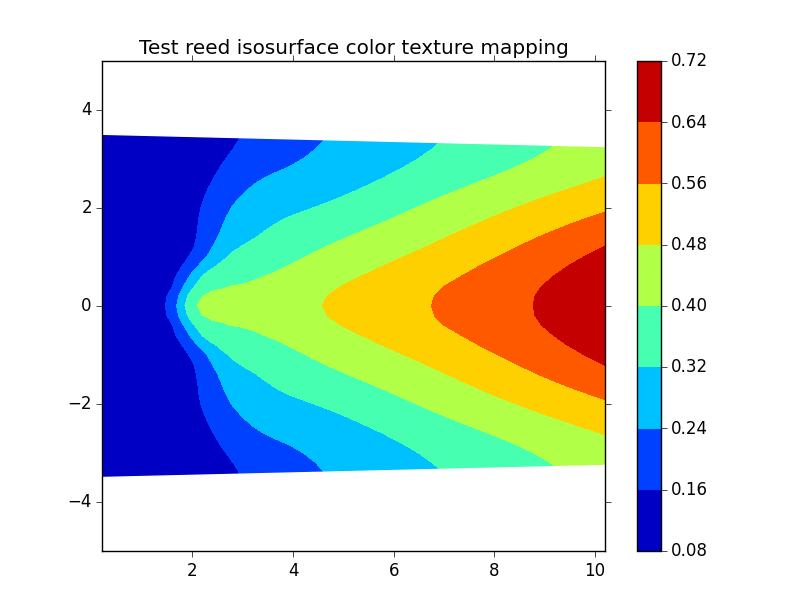

The thickness profile of the reed

The thickness profile of an oboe reed is a key element. It is used for any machine processing work on the reed wood. Because the reed is not flat it is on a cylinder the profile has been transformed to get the real or touch profile.

The touch profile

The Touch Profile is the profile which touches the sensor of the reed profiling machine. Because the touche profile is on a cylinder with a radius of 14mm (at the Wettstein machine) and 18mm (at the Reeds’n Stuff machine). The difference of the radius of the two machine does not allow interchanging ReedChips between both machines. The interchangeability is a goal because the profiling machines are expensive and especially at a student workplace it could increase the usability of the machines if a student can use a free machine with his customized ReedChip template profile.

The surface at the touch profile is a transformation of the thickness profile dependent of the distance between the sensor touch point to the axis of shape tool machine, (radius 14mm Wettstein, 18mm Reeds’n Staff)

After this transformation the touch profile will be ready to build the real ReedChip.

Adapter to connect the ReedChip to a profiling machine

The adapter to fix the ReedChip on a profiling tool will be supported. We hope the number of different adapters to the different machines will be limited. The best case would be if a standard adapter for the ReedChip will be accepted by the companies of the profile machines.

We hope on the market there will be a very low price profile machine but still the minimal functionality (keep and fix the reed, a cutting systems, the adapter for the reed chip and an accurate adjustment of the basic thickness of the reed).

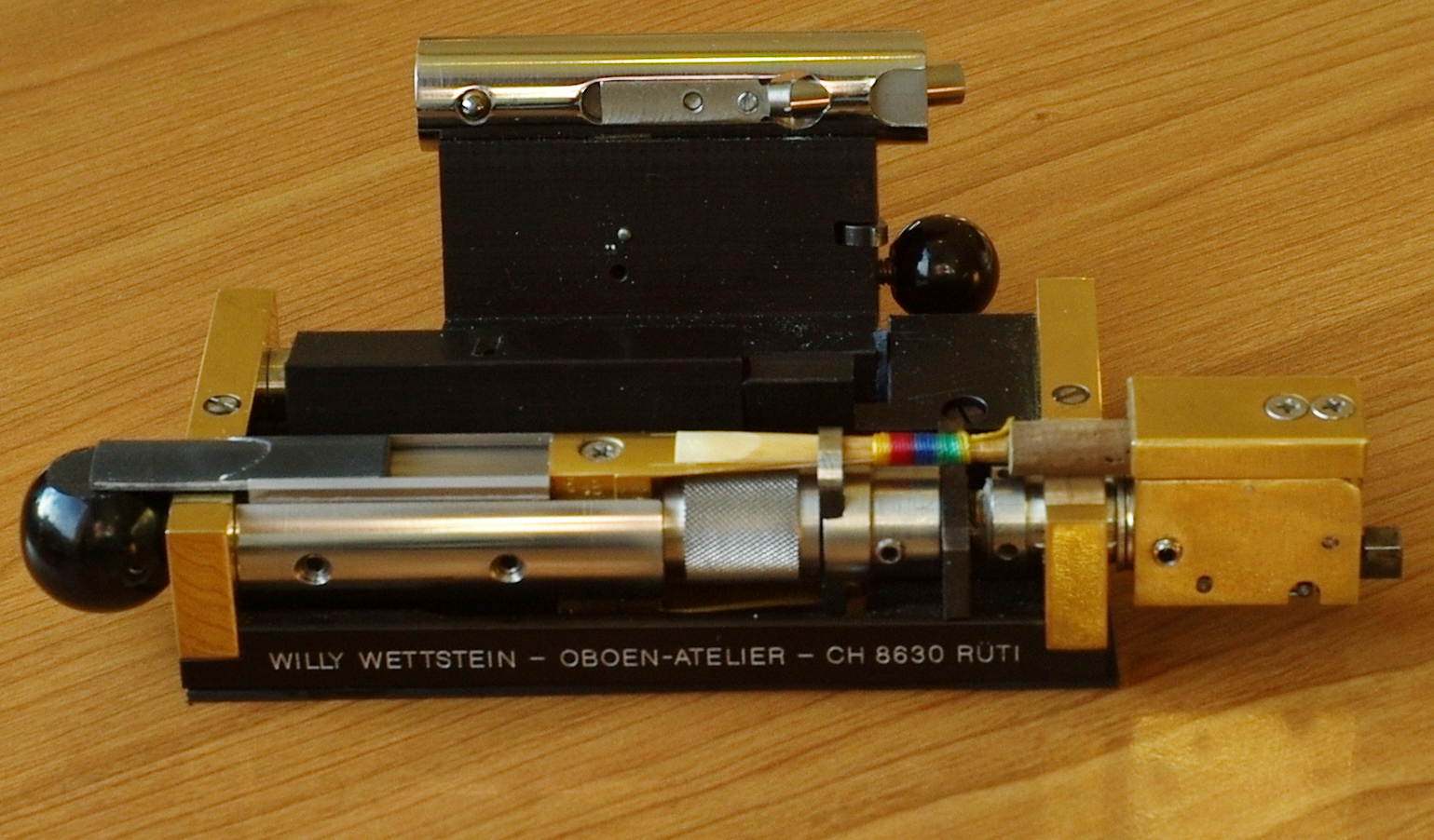

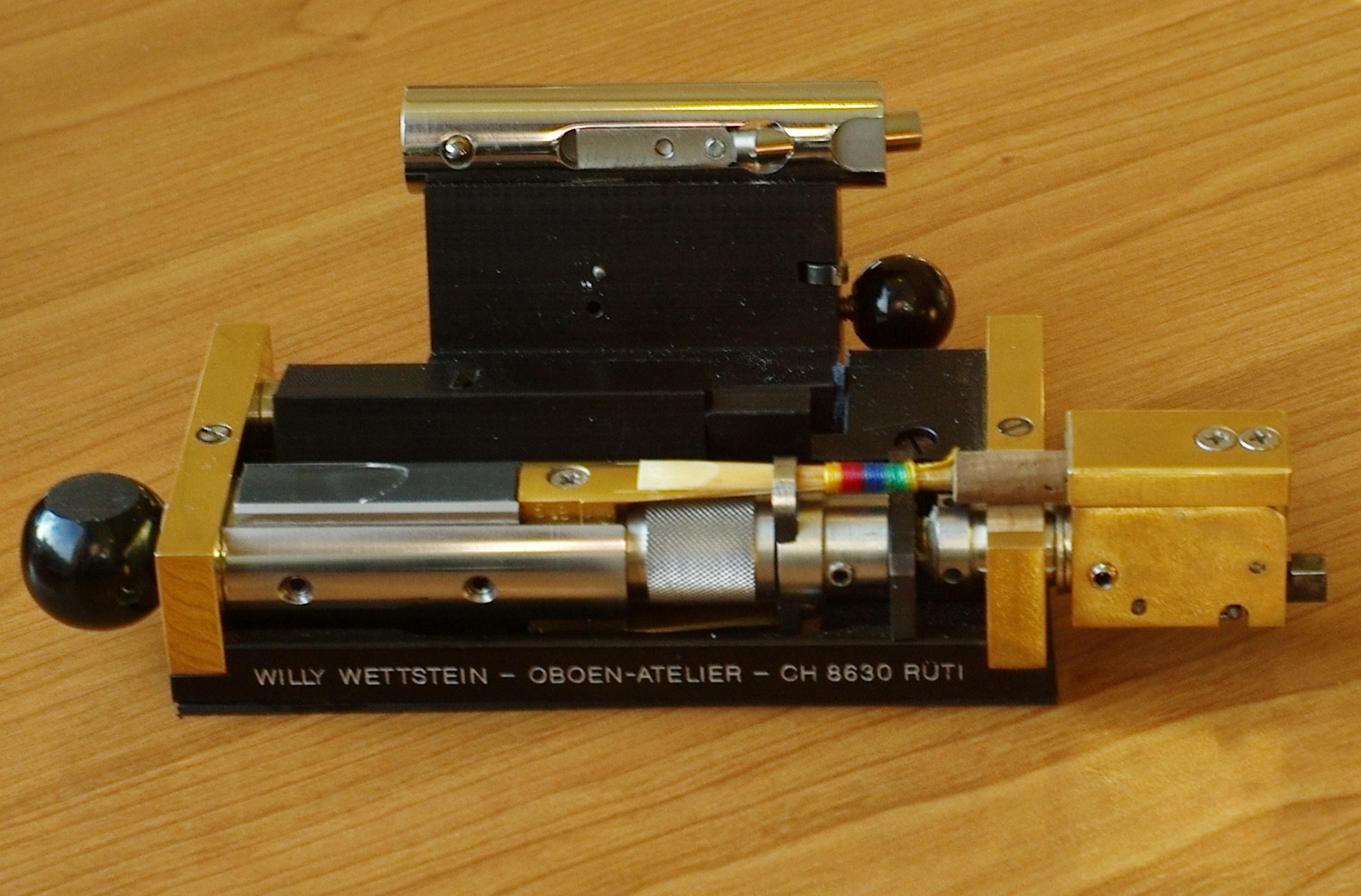

On this picture the current steel template for a customer is mounted on the block (middle left).

This template has to be changed to an adapter holding the the ReedChip.

Reeds'n Stuff profiling tool, sensor (left top), original template (left), the cutter (right) and the reed in the machine ready to make the shape (right)

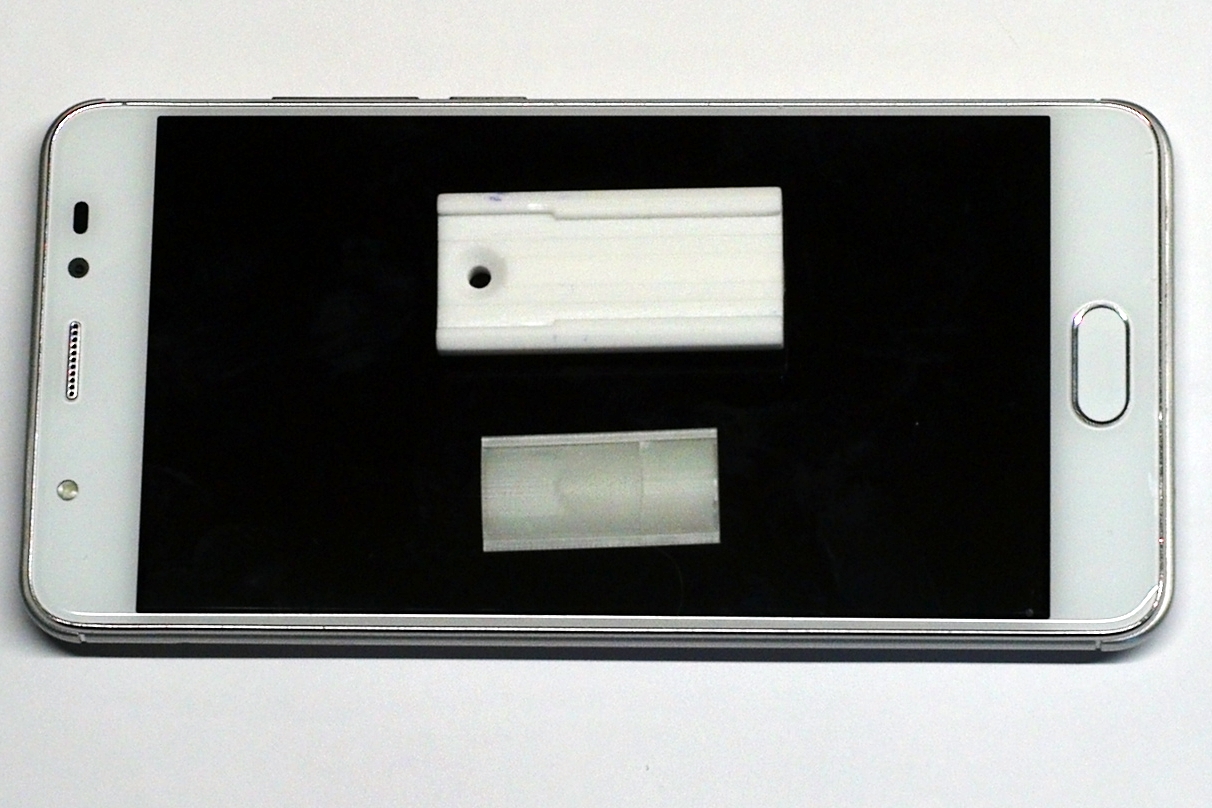

Interface and ReedChip for Reeds'n Stuff profiling machine

ReedChip inserted by finger touch into the interface.

ReedChip inserted

Wettstein profiling machine together with interface and ReedChip in action

Building the ReedChip

The thickness profile will be defined and created online via standard browser.

No additional software tools locally will be used.

Start with standard profile or with a profile from a friend.

Customize this profile.

Save this profile locally for later use.

The thickness profile will be transformed to the thicknessprofile after selecting the profiling machine. The 3D object will be generated and saved locally. With this result the user is ready to make an order to a 3D service, e.g. www.shapeways.com to print the 3D object (ReedChip).

The advantage of a ReedChip

Create fast and low price customized reed profiles in the order of 10$. Interchangeability and independency of the profile manufactures makes it easy to apply profiles from friends and share it to the social community. Users can optimize their reeds in a process oriented approach: Print - Play - Optimize - Print - Play ...

Contact and Infos.

CustomReed

Alte Bettswilerstrasse 7a

CH-8344 Bäretswil

Schweiz

info@customreed.com